Thermal insulators are essentially characterized by their thermal resistance and thermal inertia.

Thermal resistance is defined as difficulty that a product of a given thickness presents in allowing heat to pass under unit surface conditions, temperature difference and time. By definition, it is ratio of thickness to thermal conductivity.

Thermal inertia is physical ability of a material to maintain its temperature.

The best insulators are air, polyurethane foam, fiberglass, cork (expanded), glass foam, wood fiber sheeting, sponge rubber, PVC, expanded vermiculite, sawdust, loose vermiculite, and linoleum.

Thermal insulation primarily represents economy, because by preventing heta transmission, passage of energy from one body to another is avoided. In addition, thermal insulation represents an investment that will be recovered in a relatively short time, with energy savings that will be obtained, and with best efficiency and operation of equipment and machinery.

If solar thermal system is not thermally insulated there will be a loss of heat and to counteract this phenomenon system will have to resort to auxiliary energy to be able to maintain the required temperature. Therefore, if the system is thermally isolated, heat loss will be avoided and solar energy will be used, preventing auxiliary energy equipment from being activated.

Thermal insulation will also represent protection for personnel who may be in accidental contact with hot surfaces.

Characteristics of a good insulator:

1. Low heat conductivity.

2. Lightweight (do not burden system weight)

3. Fireproof and rot resistant

4. That it is not attacked by rodents or insects and that it does not breed insects

5. Inert

6. Easy to place.

Places where insulation is most relevant are: collectors back, pipes and accumulator.

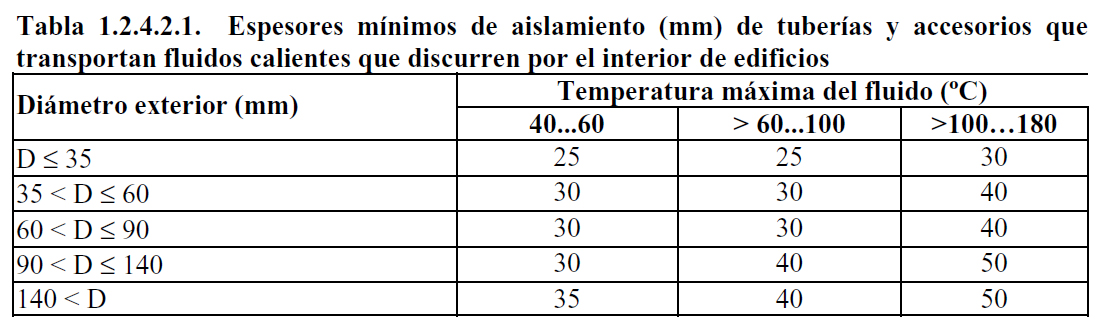

As a reference, minimum insulation thickness of interior pipes is set in Spain by the RITE (Regulation of Thermal Installations of Buildings), as indicated in the following table:

For materials with a thermal conductivity other than 0.04 W / m ºC, thickness will be determined by multiplying table value by λ and dividing by 0.04.

For pipes sections installed outside, minimum thickness indicated in the previous table must be increased by 10 mm.

The insulating material shall be secured with suitable means, so that it cannot detach from the pipes or fittings.

Insulation will not leave visible areas of pipes or accessories, leaving only the elements that are necessary for proper functioning and operation of components to the outside.

For protection of outdoor insulating material, a plaster cover or coating protected with asphalt paints, fiberglass reinforced polyesters or aluminum sheet may be used. In case of tanks or heat exchangers located outdoors, plastic fabric linings may be used.

Special care must be taken to guarantee pipes insulation durability, especially in outdoor sections exposed to sun, which must have the following insulation characteristics:

• Inalterability due to atmospheric agents and resistance to fungi formation.

• Resistance to solar radiation; otherwise, it must be adequately covered with protective covers or paints.

• Sealing of passages to outside and elimination of thermal bridges.

This content was extracted from the Solar Thermal Energy Technical-Commercial Manual and is part of Solar e-learning.

All you need is Sun. All you need is Sopelia.