Sorry, this entry is only available in Español.

PV Modules Support Structure

Regarding situation of photovoltaic modules, there are the following general possibilities:

Flooring: It is the most usual way of installing modules groups (especially in solar farms) and has great advantages in terms of wind resistance, accessibility and ease assembly.

However, it is more susceptible to being buried by snow, flooding or being broken by animals or people.

Pole: very used in small dimension systems, if it has a mast. It is the typical assembly type of isolated communication equipment or lampposts feeding.

Wall: good anchor points must be available on a built building. Accessibility can present some problems.

Roof: one of the most common because generally enough space is available. It also presents problems of snow cover and risks in roof fasteners waterproofing.

If system is located in an urban area, most common is to place the module on the roof.

In structure assembly, roof sealing must be ensured by waterproofing elements use.

A study must also be carried out to determine if ceiling will support modules and support structure weight.

However, main factor when fixing the structure is wind strength. Structure must withstand winds of at least 150 km / h.

On terraces or floors, the structure should allow a minimum height of the module of about 30 cm. In mountain areas or where there is abundant snowfall, it must be higher.

The structure and supports should preferably be anodized aluminum, stainless steel or galvanized iron and stainless steel fasteners.

Anodized aluminum is lightweight and highly resistant.

Stainless steel is suitable for very corrosive environments and has a longer useful life but its cost is high.

Galvanized iron structures offer good protection against external corrosive agents with the advantage that zinc is chemically compatible with lime and cement mortar, once these are dry.

Structures come in kits or standard profiles that are on the market and a specific system structure can be built.

Supports designed for a specific solar module are usually cheaper than those manufactured in order to be able to hold any type of module. However, it will surely be the latter that will end up developing in greater numbers in near future.

Normally, a solar modules support has the following characteristics: it has a plate provided on its upper face with quick coupling means for modules and one or more holes for the screws to be introduced and thus join the plate to the support. The support also has fastening means attached to plate lower face for fastening to lower structure.

Orientation will always be towards the equator and the following inclinations are recommended:

– Systems with priority function in winter (eg: mountain lodge): 20º higher than place latitude.

– Systems with uniform operation throughout the year (p.e .: home electrification): 15º greater than place latitude.

– Systems with priority operation in spring and summer (p.e .: campings): same as place latitude.

– Systems whose objective is to produce the greatest amount of energy throughout the year (eg: connection to the grid): 85% of place latitude.

The reason for inclination increasing, compared to that recommended for solar thermal collectors, is that generally in the case of photovoltaic systems there is no auxiliary energy system and it is necessary to capture all the energy possible in the most unfavorable period (winter).

Sopelia has developed Solar Layout, the Android App that allows you to obtain the inclination, orientation and distance between rows of photovoltaic modules at the installation site.

This content was extracted from the Solar Photovoltaic Energy Technical-Commercial Manual and is part of Solar e-learning.

All you need is Sun. All you need is Sopelia.

Solar Thermal System Protection

The correct design of a solar thermal system involves foreseeing all the circumstances that may damage it and applying strategies that can prevent breakdowns that shorten its useful life.

There are basically 5 aspects to keep in mind:

I-Frost protection:

Protection method will depend on the heat transfer fluid used and specific weather conditions of system site.

It is not enough to protect only the collectors. Outer pipes must also be protected.

As anti-frost protection systems, following could be used:

1. Antifreeze mixtures: it is the most used solution to system protection from freezing danger.

2. Water circuits recirculation: this system is suitable for climatic zones in which periods of low temperature are of short duration.

3. Automatic drainage with fluid recovery: this system requires the use of a heat exchanger between collectors and accumulator to maintain hot water supply pressure in it. This solution is not recommended in case collector absorber is made of aluminum.

4. Outdoor drainage (only for prefabricated solar systems): this system is not allowed in custom solar systems.

5. Total system shutdown during winter: this solution is advisable for systems that are only used in summer and it should be taken into account that empty circuits are subject to greater corrosion risks.

6. Collectors heating by an electrical resistance.

7. Collectors capable of withstanding freezing: there are collectors on the market that have sufficient elasticity to withstand volume increase due to freezing.

8. Introduction in absorber circuit of elastic and watertight capsules containing air or nitrogen. By increasing pressure due to freezing, they are compressed avoiding failure due to breakage.

II-Overheating protection:

An excess of heat in solar thermal systems occurs when there is too much solar uptake in relation to energy obtained consumption. When this happens, collectors retain the heat that has not been evacuated and raise its temperature to levels that can be dangerous for system.

It is estimated that a heat transfer fluid e temperature xceeding 90 ºC becomes dangerous for the system.

Problem arises when, for reasons already mentioned, temperature rises too high in collectors and the heat transfer fluid circulating inside primary circuit begins to boil, expand and emit steam.

Both dilation and vaporization raise the pressure inside the primary circuit.

On the other hand, when heat transfer fluid begins to boil in the primary circuit, scale builds up on surfaces of the various components that deteriorate equipment.

In collectors overheating, 3 cases can occur:

1. Closed circuit with outdoor expansion vessel: steam produced goes outside. This can cause scale and risk of emptying part of circuit, forcing it to be filled before it is put into service.

2. Open circuit (consumption water passes through collectors): if boiling pressure exceeds network pressure, the produced steam will discharge into network contaminating the water.

3. Closed circuit and closed expansion vessel: when temperature rises, pressure rises and safety valve will open when it reaches a certain predetermined value.

Overheating risk in storage is lower and it can be said that it could only occur if system has high performance collectors (eg, vacuum tube collectors) and lacks a dissipation mechanism.

When water is hard (content of calcium salts between 100 and 200 mg / l), necessary precautions shall be taken so that working temperature of any point of consumption circuit does not exceed 60 ° C, without prejudice to necessary requirements against legionella application.

In any case, necessary means will be available to facilitate circuits cleaning.

In addition to safety elements there are other mechanisms to avoid overheating dangers:

• Use an organic fluid with a high boiling point.

• Angle of inclination of collectors higher than optimal to capture solar radiation preferably in winter. This ensures that the most perpendicular rays of summer fall with greater inclination on collector and take less advantage.

• Excess heat poured into the pool.

• Eaves. Through arrangement of strategically placed eaves it is possible to reduce the solar radiation that solar collectors support in summer.

• Cover collectors with covers.

• Heat sinks. These devices circulate superheated liquid through ducts to dissipate its heat in the air.

Some direct all the superheated flow of primary circuit to a unit where heat is dissipated with the help of fans (air heaters).

Others, however, are structures that are placed in each collector or battery of collectors and that dissipate only heat generated by the unit they are on. This type of heatsink works by gravity, without electronic components and is activated by means of thermostatic valves. It has the advantage that it continues to work in the event of a power cut.

III-Pressure resistance:

In case of closed systems, maximum working pressure of all components shall be taken into account. The component that has the lowest maximum working pressure is the one that will set the pattern for entire system.

In case of open consumption systems with network connection, maximum pressure of the same shall be taken into account to verify that all components of the consumption circuit support said pressure.

IV-Reverse flow prevention:

System installation must ensure that no relevant energy losses due to unintentional inverse flows occur in any hydraulic circuit of the system.

The natural circulation that produces the reverse flow can be favored when the accumulator is below the collector, so it will be necessary to take, in those cases, the appropriate precautions to avoid it.

In systems with forced circulation, it is advisable to use a non-return valve to avoid reverse flows.

V-Legionellosis prevention:

It must be ensured that water temperature in hot water distribution circuit is not lower than 50 ° C at the furthest point and before the necessary mixture for protection against burns or in the return pipe to accumulator. System will allow water to reach a temperature of 70 ° C. Consequently, the presence of galvanized steel components is not admitted.

This content was extracted from the Solar Thermal Energy Technical-Commercial Manual and is part of Solar e-learning.

All you need is Sun. All you need is Sopelia.

Mexico Solar PV

Mexico is part of the solar belt, an area that considers countries with the highest solar radiation in the world.

The country set itself the goal of generating, by 2024, 35% of electricity with clean energy (currently 80% is generated with hydrocarbons).

It is estimated that solar energy will represent 13% of all energy for next year, and that their participation will gradually grow.

However, solar technology development, as in all Latin American countries (and almost entire world), presents a huge imbalance between large-scale projects and distributed generation.

As far as large-scale projects are concerned, with 37 solar power plants under construction and an estimated investment of US$ 5,000 million, Mexico aims to become a solar power thanks to regulatory support and enviable geographic conditions.

In Coahuila is the largest solar park in Latin America with an investment of US$ 650 million generates about 754 MW.

By the end of 2020, the country will have 5,000 MW of installed capacity.

This impulse is due to the Energy Reform that opened the sector to private initiative, the Energy Transition Law and the three electric auctions held to date.

Average price obtained in the third solar auction (in which contracts were assigned to 9 projects) represented a downward world record for all energies.

In sector, presence of foreign actors stands out, winning approximately 90% of the bids.

The other side of the coin is that of distributed generation.

Although since 2007 it is possible to install solar panels in homes, shops and industries and connect them to the electricity grid; until 2017, necessary conditions distributed generation development were not created. It represents less than 0.3% of total electricity generation in Mexico.

Before Energy Reform, distributed generation could only be used for self-consumption (and surpluses were lost after 12 months), without it being possible to buy or sell photovoltaic solar energy.

Regulations approved in March 2017 regulate the following compensation models: 1) Net metering; 2) Net billing; 3) Total sale.

In addition, due to ignorance advantages of using solar energy, which could supply a home with high electricity consumption, with only 16 square meters of photovoltaic panels, are lost in Mexico.

Most people are unaware that installing a renewable technology system based on solar panels in their homes is legal, simple and accessible,

Another challenge to face trained personnel lack both technically, to install panels, and engineering, for systems design.

Betting only on large-scale projects is an absurd and non-logical proposal that makes renewables a financial product and not an energy policy tool that promotes employment and technological and industrial development at national level.

It favors macro projects and deepens energy sector convcentration.

Low prices concentration in auctions, with the consequent creation of a dominant position in a few actors (usually foreign companies), will in long term dilute the advantages of low short-term prices.

If we consider auctions as the only tool to increase renewables participation, we will be maintaining an obsolete energy matrix paradigm and committing a very serious error.

The future energy matrix is based on 3 pillars:

1) Energy efficiency

2) Renewable energies

3) Distributed generation

The path of energy revolution and citizen empowerment goes through prosumer figure development and energy cooperativism.

The way of concentration and centralization involves only changing fossils for renewables to maintain the “status quo” for benefit of those who always will continue to act as a collection agency in collusion with political party in government.

All you need is Sun. All you need is Sopelia.

Solar Wiring

Cables, both direct current (DC) and alternating current (AC), if correctly sized, will minimize energy losses and protect the installation.

For a photovoltaic system, DC cables must meet some requirements:

* Have grounding line and protection against short circuit.

* Be resistant to UV rays and adverse weather conditions with a wide range of temperatures (approximately between -40ºC and 110ºC).

* Possess a wide voltage range (more than 2000 V).

* Be simple and easy to manipulate.

* Be non-flammable, of low toxic level in case of fire and without halogens.

* Have a very low conduction loss (up to 1%).

Photovoltaic installation cables must have certain characteristics that differentiate them from conventional cables, although many argue that differences are not very large.

Since voltage in a photovoltaic system is low DC voltage, 12 or 24 V, currents that will flow through the cables are much higher than those in systems with 110 or 220 V AC voltage.

Power amount in Watts produced by the battery or photovoltaic panel is given by the following formula: P = V. I

V = voltage in Volts

I = current in Amperes

This means that to supply a power at 12 V current will be almost 20 times higher than in a 220 V system. It implies that much thicker cables must be attached to prevent overheating or even a fire.

Following table indicates recommended cable section according to power and for different voltage levels.

For very low voltages and low power demands, very thick cables must be used. For example, to reach a power of approximately 1 Kw at 12 V we would need a 25 mm2 section cable. The same as to supply 20 Kw at 220 V.

This increases system price drastically because thicker cables are more expensive.

That is why it is very important that the lengths of DC wiring are as short as possible.

When designing large systems, a cost / performance analysis must be performed to choose most suitable operating voltage. It would be advisable to gather small groups of modules and if possible to make operating voltage higher than 12 or 24 V.

To verify cable section values recommended in tables, maximum voltage drops compared to voltage at which you are working should be below the 3% / 5% limit.

To calculate the relationship between conductor section and its length we can apply following formula:

S = 2 r. l. i / ΔV

Being:

r Conductive material resistivity (0.018 in case of copper conductors)

l Cable section length

i Current intensity

ΔV Voltmeter reading difference

Let’s see an example:

Battery terminals output voltage is 13.1 V. The main line between it and a device, which consumes 60 W, measures 12 m of 6 mm2 cable.

We must find the voltage value at device input to verify that we are within maximum recommended values of voltage drop.

The intensity i = P / V = 60 / 13.1 = 4.6 A

S = 6 = 2. 0.018. 12 4.6 / ΔV

ΔV = 0.33 V

Therefore, voltage at device input will be: 13.1 – 0.33 = 12.8 V

Voltage drop is 2.34% (maximum recommended value: 3%).

It is normal to use tables to select recommended section and use the formula to calculate the voltage drop and perform the verification.

In case that voltage recommended maximum values drop are exceeded, we will select section immediately above and we will carry out verification again.

Cables for photovoltaic applications have a designation, according to regulations, which is composed of a set of letters and numbers, each with a meaning.

Cables designation refers to a series of characteristics (construction materials, nominal voltages, etc.) that facilitate the selection of the most suitable to the need or application.

This is an extract of contents included in Technical-Commercial Photovoltaic Solar Energy Manual and Sopelia e-learning training.

All you need is Sun. All you need is Sopelia.

Heat Transfer Fluid

Heat transfer fluid passes through absorber and transfers energy to thermal utilization system (accumulator or exchanger).

Most used types are:

* Natural water: can be used in open circuit, when sanitary water passes directly through collectors, or in closed circuit (independent consumption circuit).

In first case, circuit can only be constituted by materials allowed for drinking water supply. In some countries this system is not allowed.

It will be necessary to consider water characteristics, especially its hardness (calcium and magnesium amount), which when heated produces a hard crust or tartar.

This crust accelerates corrosion, restricts flow and reduces heat transfer. The values start to be problematic from 60 mg / l. Very soft waters can also cause problems due to their corrosivity.

* Water with antifreeze: to avoid drawbacks of freezing and boiling of heat transfer fluid, use of antifreezes called “glycols” is the most widespread.

Mixed with water in certain proportions prevent freezing to a limit of temperatures below 0 ° C depending on their concentration.

On the other hand the boiling point rises making heat transfer is protected against too high temperatures.

Choice of concentration will depend on historical temperatures of the area where installation is located and on characteristics provided by manufacturer.

Most commonly used glycols are ethylene glycol and propylene glicol.

Fundamental characteristics of antifreeze:

• They are toxic: their mixing with drinking water must be prevented by making secondary circuit pressure greater than that of primary, for prevention exchanger possible breakage.

• They are very viscous: factor to take into account when choosing electric pump that is usually more powerful.

• Dilates more than water when heated: as a safety standard, when we use antifreeze in proportions of up to 30%, when sizing the expansion vessel, we will apply a coefficient of 1.1 and 1.2 if proportion is greater.

• It is unstable at more than 120ºC: it loses its properties so it stops avoiding freezing. There are some that withstand higher temperatures, but they are expensive.

• The boiling temperature is higher than that of water alone, but not too much.

• Specific heat is lower than that of water alone, so it must be taken into account in the flow calculation, conditioning pipe and pump dimensioning.

To calculate antifreeze amount that must be added to an installation, you must first consult the table of historical temperatures which is the minimum temperature recorded in that city or location.

Once it is known, goes to glycols graph supplied by manufacturer and value is transferred to indicate what percentage is.

* Organics fluids: there are two types, synthetic and petroleum derivatives.

Precautions mentioned in case of antifreeze regarding toxicity, viscosity and dilation are applicable to organic fluids. Additional risk of fire should be mentioned, but also that they are chemically stable at elevated temperatures.

* Silicone oils: they are stable and of good quality products. They have the advantages that they are not toxic and that they are not flammable, but current high prices mean they are not widely used.

All you need is Sun. All you need is Sopelia.

(Español) Beca Solar

Mexico Solar Thermal

As in most Latin American countries, in Mexico, statistics in solar thermal energy field are not up-to-date and renewable energies prospects do not include this source of generation.

In Mexico, in 2010, solar systems to heat water were installed in an equivalent area of 272,580 m2, reaching an accumulated area of 1,665,502 m2.

According to estimates, in next 4 years almost double the production area by solar thermal energy.

Although we do not find data about current installed capacity in Mexico, we can conclude that this type of energy has had a great growth in recent years and that it is likely that the installed capacity has doubled again.

Due to country average radiation levels, a solar thermal installation for domestic hot water has become a very profitable investment in Mexico, since water heating causes the greatest gas consumption and with this application, gas use is reduced by up to 80% in regions with higher radiation.

Recently there has been a noticeable decrease in prices of solar equipment for domestic hot water.

The factors that allow this to happen are imports, easy manufacturing, technology maturity and competitiveness between national and international companies that offer this type of equipment.

In Mexico, there are important companies that manufacture low temperature thermal solar energy equipment. The first began in 1940 in Guadalajara.

Several government programs have promoted low cost acquisition of solar heaters by residents of areas where the gas network does not reach.

Other solar thermal energy applications that have increased considerably are swimming pools conditioning and water heating for industrial processes.

Hermosillo was one of the first states to adopt this type of technology for industrial processes in Mexico.

A cement company uses a thermal 291 KW equipment to operate a 75 tons of single effect cooling system. This was the first air conditioning system based on renewable energy in Latin America. The parabolic cylindrical collectors are located on the roof and on one side of corporate building; it operates in a range from 70 ° C to 95 ° C.

Other systems have been installed for generating heat purpose.

Mexican companies have commercially developed parabolic-linear solar concentrators to generate thermal energy between 50 ° C and 200 ° C. These systems are used mainly in food sector.

Some of the companies that currently have this alternative energy generation in the country are:

– Food company: installation of 80 solar concentrators for process heat generation and absorption chiller supply.

– Dairy company: installation of 70 solar concentrators for direct heat input in dairy products processing.

– Egg producing company: installation of 80 solar concentrators for boiler preheating.

Despite advances, there is still much room for solar thermal technology development in Mexico.

The final impulse could come from special financing lines implementation, since for a large population sector initial system investment is still very high.

All you need is Sun. All you need is Sopelia.

The Solar Converter

They are equipment capable of altering voltage and characteristics of electric current they receive to transform it into suitable for specific uses.

Those that receive direct current and transform it into direct current with a different voltage are called DC-DC converters. They are not widely used in photovoltaic systems.

Those that receive direct current and transform it into alternating current are called DC-AC converters or inverters. The function of an inverter is to change a DC input voltage to a symmetrical AC output voltage, with the magnitude and frequency desired by user.

They allow to transform 12V or 24V direct current that modules produce and store batteries, in 125V or 220V alternating current.

This allows use of electrical devices designed to work with AC.

A simple inverter consists of an oscillator that controls a transistor, which is used to interrupt incoming current and generate a square wave. This square wave feeds a transformer that softens its shape, making it look like a more sinusoidal wave and producing the necessary output voltaje.

The voltage output waveforms of an ideal inverter should be sinusoidal.

This gives rise to different types of inverters:

1) Square wave inverters: they are cheaper, but less efficient. They produce too many harmonics that generate interference (noise). They are not suitable for induction motors.

Recommended if you want AC power only for a TV, a computer or a small electrical device. Inverter power will depend on device nominal power (for a 19 ” TV a 200 W inverter is enough).

2) Modified sine wave inverters: they are more sophisticated and expensive. They use pulse width modulation techniques.

Wave width is modified to bring it as close as possible to a sine wave. Harmonics content is less than in square wave.

They are the ones that offer best quality / price ratio for lighting, television or frequency inverters connection.

3) Pure sine wave inverters: with a more elaborate electronics, a pure sine wave can be achieved.

Until recently these investors were large, expensive and inefficient; but lately, has been developed equipment with 90% or more efficiency, telecontrol, energy consumption measurement and battery selection.

Since only induction motors and most sophisticated devices or loads require a pure sine wave form, it is usually preferable to use modified sine wave inverters; which are cheaper.

Inverters must be dimensioned from two variables.

First is considering electrical power wattages that inverter can continuously supply during its normal operation.

Inverters are less efficient when used at a low percentage of their capacity. For this reason it is not advisable to oversize them and they must be chosen with a power as close as possible to that of load consumption.

Second is starting power. Some inverters can supply more than their nominal capacity for short time periods. This capacity is important when using motors or other loads that require 2 to 7 times more power to start than to stay running once they have started (induction motors, high power lamps).

Incorporating an inverter is not always the best option from energy efficiency point of view. It may seem an easy solution to convert all solar system output to a standard AC power but it has several disadvantages.

First is that it increases system cost and complexity.

An inverter also consumes energy (in addition to 15% for performance loss) and therefore decreases overall system efficiency.

For a small house electrification (light points, TV and a small appliance) it is possible and profitable to do without the inverter.

For lighting it is better to invest in low voltage lights instead of investing in an inverter.

Laying of 2 lines can be interesting: one connected to batteries to feed points of low consumption lighting or LED and devices that consume DC and another connected to inverter to power appliances that consume AC.

The advantage of the inverter is that operating voltage is much higher and therefore the use of thick cables can be avoided. Especially when wiring is extremely long it may be economically feasible to use an inverter.

A feature that incorporates most modern converters is possibility of operating as battery chargers, taking alternating current from a generator or grid.

This is an extract of contents included in Technical-Commercial Photovoltaic Solar Energy Manual and Sopelia e-learning training.

All you need is Sun. All you need is Sopelia.

Solar Collectors Clamping And Anchoring

Proposed solution must comply, in order of importance:

– That it’s enough safe .

– That its cost be as low as possible.

– Speed and simplicity in assembly.

A method currently used is anchoring by chemical plug.

There are structures are of different materials. The most commonly used are aluminum and stainless steel.

Manufacturers usually sell the collector with its structure, although you can always design your own structure.

It is not advisable to transfer building cover with the anchor (it can cause leaks).

In case of large installations, a pre-assembly work can be carried out to make assembly on roof faster and cheaper.

In near coast areas, structure must be hot dip galvanized.

Screws should be made of stainless steel or corrosion resistant material.

Anchoring type will be based on:

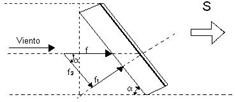

1) Wind forces that must endure. If collector is South oriented (we are in the Northern Hemisphere), wind that represents a risk is that coming from North (it is the inverse if we are in the Southern Hemisphere), which will exert tensile force on the anchors. The South wind will exert compressive force, not so dangerous. Wind force on a surface is:

f = P. S. sen2α

f = Weight to counteract wind strength.

P = wind load (Kg / m2).

S = collector surface (m2).

sin2α = angle of inclination sine.

Wind force is decomposed into f1, which incites perpendicularly to collector surface and in f2, which does it in parallel.

f1 force is at the end what counts and what is obtained from previous formula.

2) Collectors orientation and inclination. Collectors are oriented towards Ecuador. Normally, if we are in Southern hemisphere, they are oriented towards North and vice versa. Deviations of up to 20% with respect to optimal orientation do not significantly affect system performance and thermal energy contributed.

Collector’s inclination angle will depend on solar equipment use. Orientates inclinations:

• All year use (H.W.S.): inclination angle equal to geographical latitude.

• Winter preferably use (heating): inclination angle equal to geographical latitude + 10º.

• Summer period preferred use (outdoor pools heating): inclination angle equal to geographical latitude – 10º.

Variations of ± 10º with respect to optimum inclination angle practically do not affect performance and useful thermal energy provided by solar equipment.

3) Collecting surface must be free of shadows. In the most unfavorable day of use period, installation must not have more than 5% of useful surface area covered by shadows.

Projected shadows practice determination is made observing environment from collector´s lower edge midpoint, taking the North-South line as a reference.

By making an angular sweep on both sides, we will try to locate nearby obstacles with an angular height greater than 15º / 25º.

A more accurate determination of possible shadows can be made using system sizing software based on simulation methods.

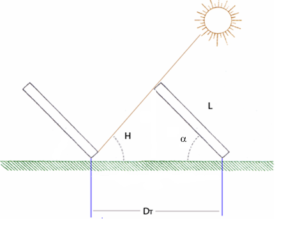

4) Minimum distance between collectors. Separation between collectors rows must be established so that at solar noon of most unfavorable day (minimum solar height) of use period, the shadow of upper edge of a row will be projected, at most, on lower edge of following row.

The formula of minimum distance between collectors is:

DT = L (senα / tan H + cosα)

H is the minimum solar height, which is:

H = (90º – latitude place) – 23.5º

L is collector´s height

If collector’s rows were arranged on a non-horizontal surface, expression would become:

DT = L ((sin (α – β) / tan (H + β) + cos (α – β))

α is still collector inclination angle respect to horizontal.

β is roof inclination angle respect to horizontal. It is positive if cover inclination angle direction coincides with that of collector; and with a negative value otherwise.

5) Finally, calculations must be carried out to ensure that cover or support will be able to support collectors weight, and that of the tank in case of thermosiphon and compact systems.

The R + D + I area of Sopelia has developed Solar Layout, the mobile app that allows collectors and modules to be optimally located at installation site.

All you need is Sun. All you need is Sopelia.