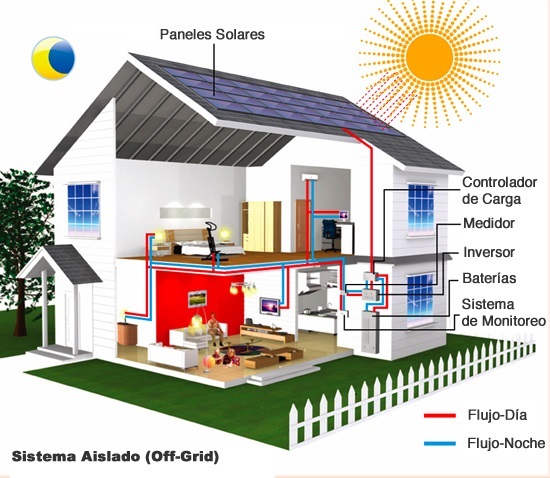

Without batteries, off-grid PV systems (except some cases such as water pumping) would be meaningless, because their functionality depends on electrical energy storage.

The battery is an electrochemical device that transforms chemical energy into electrical energy, whose presence is necessary because solar modules only generate energy when light hits them.

In addition, sometimes battery provides an instantaneous power higher than that of modules (eg: for starting motors) and provides stable and constant voltage regardless of light incidence.

The battery determines modules operating voltage. Therefore a safety margin is required which will mean a small loss (about 10%) with respect to maximum power that module could provide at higher voltages.

There is no ideal battery. The choice is a compromise between economy and suitability starting from a minimum quality that provides reliability and long life to the system.

In a battery, we have to take into account 3 technical considerations:

1º The discharge capacity

It is the maximum amount of electrical energy that can be supplied from its full charge to its complete discharge. Measurement unit is the amp hour.

The loading and unloading ratio and the battery and environment temperature are factors that can make vary its capacity.

2º The discharge depth

In renewable energy systems, only deep discharge batteries are used (we refer to capacity percentage that is used in a cycle of loading and unloading).

Deep discharge batteries have an average discharge of 25%, and can reach 90%.

3” Cycles of a battery

It is the time from complete charge to discharge.

Battery life is measured in number of cycles it can handle.

Auto-discharge should also be considered as an additional consumption that daily demands a certain percentage of stored energy.

As damaging as excessive discharge is for a battery to too much load. Way to prevent this is by introducing a charge controller.

Every time battery is recharged, does not completely regenerate, resulting in a degradation that will determine battery life.

If discharge depths are respected and maintenance is correct, battery service life should be approximately 10 years.

For PV systems, batteries used are:

1. Lead-Acid: Characterized by their low cost and maintenance they require (need to be in a cool place and periodically check electrolyte amount).

Lead-antimony are the most used in medium and large systems and lead-calcium are mainly used in small systems.

There are also 2 types of sealed lead-acid batteries: Gelled (incorporating an electrolyte gel type) and Absorbed Electrolyte (electrolyte is absorbed into a microporous glass fiber or a polymer fiber web).

These batteries don´t require maintenance in water aggregate form nor develop gases, but both require less deep discharges during their service life.

2. Nickel-cadmium: offer better performance, but have a higher price.

The electrolyte they use is an alkaline, have a low self-discharge coefficient, good performance at extreme temperatures and the discharge they support is around 90% of their rated capacity.

They are recommended for isolated or dangerous access places.

They can´t be tested with same reliability as lead acid. Therefore, if it is necessary to control charge state, they aren´t the best option.

3. Lithium: they take up little space, they weigh less, they do not emit gases, they can be put anywhere, loading time is the fastest, total discharges can be made without affecting their useful life in a relevant way.

What is the disadvantage? Its very high price.

The manufacturer who can optimize them will have found the solar sector Holy Grail.

This is an extract of contents included in Technical-Commercial Photovoltaic Solar Energy Manual and Sopelia e-learning training.

All you need is Sun. All you need is Sopelia.